Share this

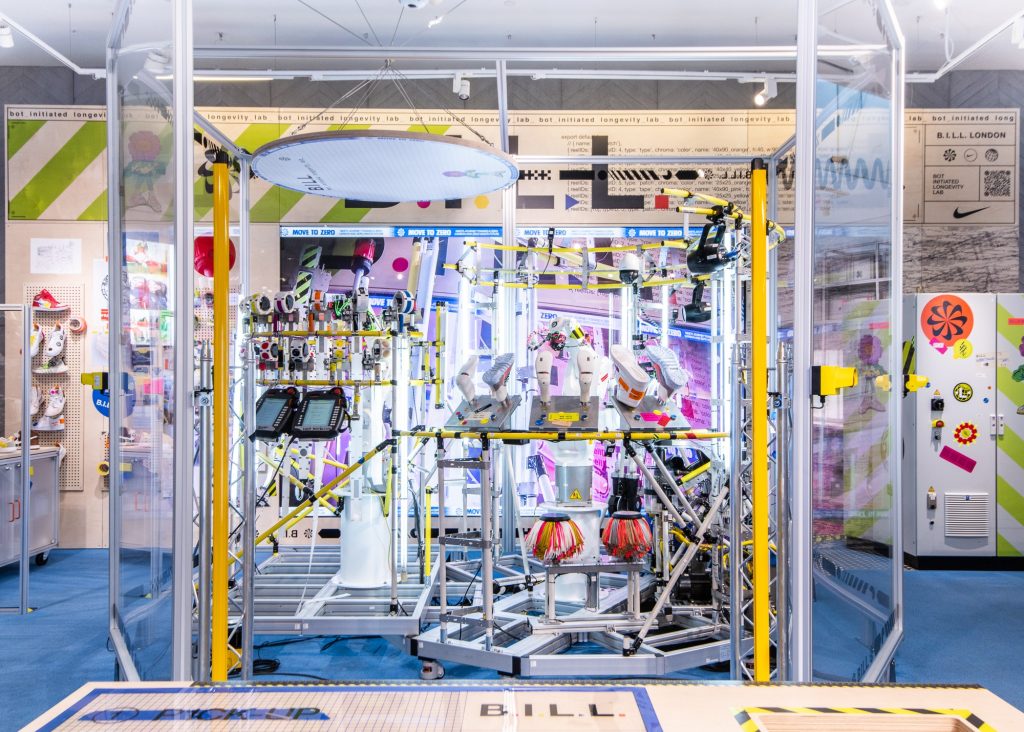

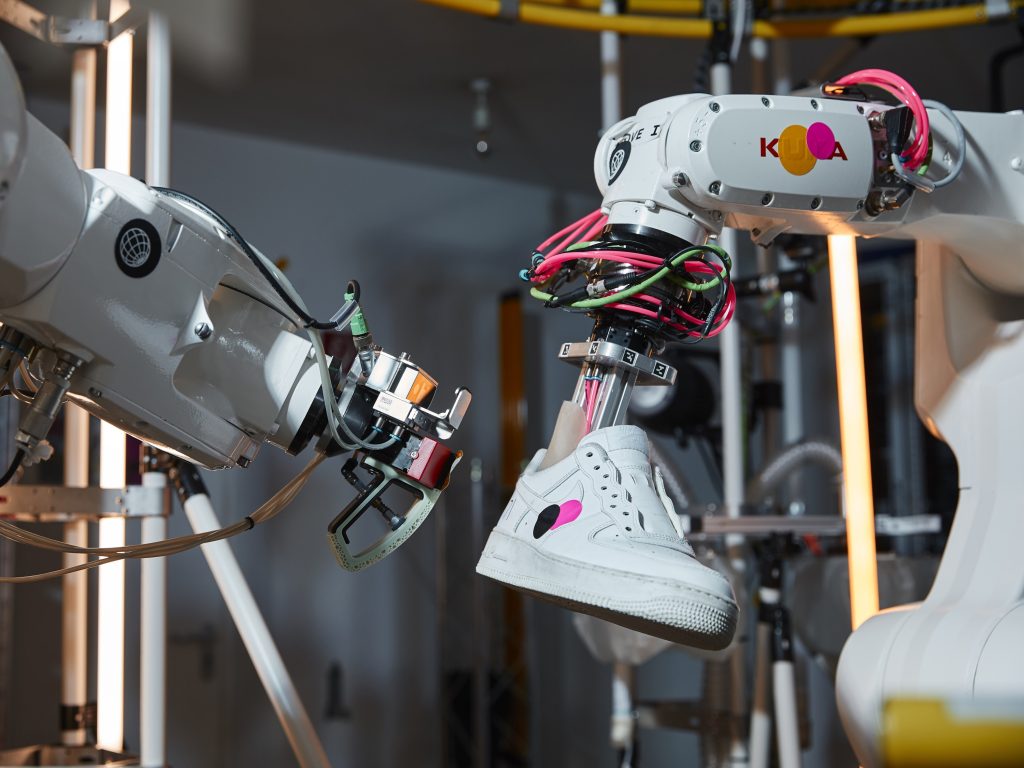

Debuting in Nike Town London, B.I.L.L. (Bot Initiated Longevity Lab), is a robot-augmented system designed to clean and repair shoes with selected customizations. Framis Italia developed the project in co-creation with Nike, providing its know-how in footwear decoration and supplying heat-welding patches.

Extending the life of product – the primary goal of B.I.L.L. – is one way to significantly reduce its impact on the planet, helping Nike chart its way toward a more circular future.

Nike’s circular vision includes products that are made with the intention of being reused, remade, rediscovered, and loved again as something brand new. Extending the life of a product is a key component of that circular future. Giving a product a second life reduces its environmental impact on the planet.

Using advanced robotics, old-school hand craft, water-based cleaning products and recycled polyester patches, B.I.L.L. is currently capable of extending the life of Air Force 1s, Air Jordan 1s, Space Hippie 01s, and Nike Dunks. After loading a shoe into the robot, a three-dimensional digital model of the shoe is created, pinpointing detailed areas of cleaning on the upper, the sidewalls, and the outsole. Shoppers can then select patches to repair areas of wear-and-tear on the upper of their shoe.

Once B.I.L.L. has finished with the shoes (all in all, B.I.L.L. takes about 45 minutes to process a pair of Air Force 1s) , Nike store athletes add new liners and laces made from recycled materials.

B.I.L.L. will be available at Nike Town London throughout September. The experience is a pilot and London will provide valuable insights that will guide the future of sustainable services in Nike doors.

Share this

Framis Italia becomes Contributor to the Roadmap to Zero Programme by ZDHC.

Framis Italia recognizes the need to manage the use and possible release of hazardous chemicals into the environment. For this reason, it has joined the Roadmap to Zero Programme of the ZDHC Foundation (Zero Discharge of Hazardous Chemicals) as a Contributor.

Becoming ZDHC Programme Contributor is an achievement in line with the ambitious sustainability goals of the Company, whose mission is to lead the challenge of sustainable growth with its partners, clients and pioneers within the industry.

The ZDHC Programme is a collaboration of organisations from the textile, apparel, leather and footwear industry. These brands, associations and affiliates - the so-called Contributors - are responsible for contributing to the development and implementation of ZDHC guidelines and solutions. They are one step ahead of developments in chemical management, helping the Programme to widespread implementation of sustainable chemistry, driving innovations and best practices to protect consumers, workers and the environment.

The Roadmap to Zero programme focuses on three areas that are linked together to improve chemical management. Within each of these three areas - Input, Processes and Output - it is a priority to develop and maintain ZDHC guidelines, platforms and solutions to enable and accelerate programme implementation.

Producing materials that are derived from chemical synthesis, Framis Italia must ensure that no hazardous substances are incorporated into its products from the beginning of the production process to create a circular process that does not produce or release harmful chemical residues. Thanks to the implementation of the ZDHC Manufacturing Restricted Substance List (MRSL), the company can therefore benefit from a structured method that periodically measures the level of application in a transparent manner.

In the future, the company’s entire product line will experience a substantial reduction in its chemical footprint. For this reason, Framis Italia is eager to work in a collaborative manner by actively engaging with all stakeholders, which are necessary to create systematic change through an open and informed dialogue.

The Company is in line with ZDHC’s belief, according to which “by empowering every point of the value chain towards safer manufacturing, we are building a new status quo. Our dynamic, determined community helps to reduce the industry’s environmental footprint. Step-by-step, we want to build a better future for everyone.”

To learn more about our ongoing commitment to reduce our impact on the planet click here, or get in touch with us through the button below.

Framis Italia has obtained the "Advanced" level of the 4sustainability® CHEM protocol for eliminating toxic and harmful chemicals in production processes.

A good chemical management system – constructed according to an approach to the process as well as the product – is probably the best example of applied sustainability. The process of elimination of chemical substances that are toxic and harmful to human health and the environment in fact takes place through the control of the entire production cycle, from the receipt of raw materials in the company to the various stages of production, to the management of waste and the introduction of the product onto the market.

The CHEM 4sustainability® protocol developed by Process Factory for the elimination of toxic and harmful substances is based, in line with ZDHC methodology, on the synthesis between what brands ask companies in the supply chain and the analysis of relative verification methods. A bringing together of demand and ability to respond oriented towards the gradual achieving of shared goals through a single management system, which is to be applied though a dedicated project, regular training and refresher courses and constant monitoring over time.

Following the various assessment audits to validate the level of implementation reached, Framis Italia obtained the certificate of "Advanced Chem Implementation Level" with a rating of 79 out of 100.

The Certificate:

To learn more about our ongoing commitment to reduce our environmental impact click here, or contact us by clicking the button below.

We are pleased to share the interview given by our Plant Manager to Repower, a leading company in energy consulting for companies, efficiency and solutions for electric mobility.

How was Framis Italia born and what did you choose to focus on?

Framis Italia was born 40 years ago from a winning idea of its founder, Mr. Luciano Salotto: to promote a new polyurethane elastic tape, Framilon®, in the world of clothing. Since then, the company has developed and improved the NoSo® heat-sealing system, meeting the growing demand for creativity and quality expressed by leading stylists and designers all over the world.

Since 2008 Framis Italia has had an office in Hong Kong and since 2016 also in the United States.

How important is innovation in your work and what implications does it have?

Our job is to propose innovative, high quality and fully integrated solutions for polyurethane thermo-adhesive applications in fashion, sportswear and footwear: we supply films, tapes and machines to top international brands and their production partners. The tape is then used on the edges of garments to reinforce the fabric and prevent breakage or loss of elasticity and to flatten seams - in underwear, sportswear and more - without weighing them down, improving the fit of garments and ensuring maximum freedom of movement. As it is available in transparent, black or piece-dyed fabric, it can also be used as a decoration, a base for embroidery and inserts.

The chemical-textile division develops and produces a wide range of textile accessories through coating plants. Recent investments in machinery and equipment have allowed us to achieve a production capacity increasingly targeted to meet the fragmented demand of the market. The mechanical division designs and develops the machines, heat-sealers, necessary for the application of textile accessories made by the chemical-textile division. This structural choice has allowed us to offer effective application technology solutions.

During the Covid-19 emergency in March 2020, you invested in a "new" production. What is it about? What impact did it have on your business?

At the beginning of the pandemic, between February and March 2020, we decided to invest in a project that involved the production of a thermoadhesive tape for overalls and gowns. Obviously, the project had to be completed in the shortest time possible, so our R&D team, working incessantly for over a month, created a certified tape - which is applied to overalls and gowns with our heat-sealing machines - for clothing protection against chemical agents (category III, 4B) and barrier against infectious agents (UNI EN 14126:2004).

This production has allowed us to create a partnership with a company engaged in the supply of suits and gowns for hospitals and healthcare facilities.

In the last four months of the year, these orders helped fill the sales gap created by the pandemic, particularly in our target sector, fashion.

How important are sustainability and efficient use of resources in your industry?

Our main customers are important brands in the fashion industry. For some years now, the topic of sustainability has been very much in the forefront in this sector. The demand is for the entire supply chain to be compliant in this sense.

Working for sustainability has become our company policy and in our new projects everything is studied in respect of the environment.

You use the Verde Dentro supply, you have obtained the ASE certificate of excellence and the VAMPA certification. How do you want to enhance and share these efficient and sustainable choices?

It is important for us to create a deep-rooted culture of sustainability and efficiency in all our employees, so that these best practices become, over time, the usual way of working.

Energy is one of the pillars of this topic, and we are aware of how important it is in terms of image to share the results obtained thanks to our efforts and commitment. That's why we're working with our marketing department and with Repower's expert advice on how best to convey this message to our customers and suppliers.

ASE Certificate of Excellence and VAMPA certification: